MCI was a tape deck and mixing console company based in Ft. Lauderdale, Florida, that was formed in 1955, and ran until 1982 when Sony bought them out. Sony then discontinued the MCI tape decks in 1984. This article will concentrate on their reel to reel tape decks, since we have not seen or worked on one of their mixing consoles to date.

There’s an excellent history of MCI on Wikipedia:

https://en.wikipedia.org/wiki/MCI_(recording_studio_gear)

The decks that we have seen from MCI are the JH-110 models, which came in JH-110A to JH-110C models. Interesting that the Wiki article doesn’t mention the very popular JH-110 2 track models, and various iterations thereof (up to the 1” 8 track model), all based on the same JH-110 transport and electronics.

Another good MCI history page, detailing more about the popular JH-110 series of decks:

The JH-24 transport was very similar to the JH-110 2 track model, however the electronics and remote control /switching of the audio is significantly different from the 2 channel models. The pros and cons of the MCI series in our opinion is as follows:

Pros

- was a budget deck designed for studio use, at a cost significantly lower than Studer

- once rebuilt, they are reliable decks

- most models are 3 speed, (7 ½ to 30 IPS) and the 16 and 24 channel decks are 2 speed (15 and 30 IPS)

- certain models can handle up to 14” diameter reels

- built in pitch control

- built in IEC/NAB equalization

- +4db XLR inputs and outputs

- they have a great ‘tape’ sound, not as flat as a Revox/Studer, but with a very appealing frequency response that adds a lot of character to recordings

- direct drive motors on all models

- relatively easy to service, with a flip-up transport, and a slide out chassis for the audio electronics

- good tape handling, with adjustable tension settings

- well written service manual which is easy to follow

- parts are fairly easily available, as many machines were sold

- many modules can be changed between the various models of the JH series, allowing even transport modules from 2 channel decks to work in 24 channel decks, and vice versa. (Downside is that not all boards can be directly interchanged, due to production changes throughout the manufacturing date range. There’s no cross-reference chart (that we know of), so interchanging modules and boards is a bit hit and miss)

- current rebuilt MCI decks are offered by Maramachines.com

Cons

- bad IC sockets. Some versions of decks used red IC sockets. The pins now are so loose that the chips can literally fall out if the sockets are held upside down, resulting in intermittent and poor contacts. These MUST be changed in order for the deck to be reliable.

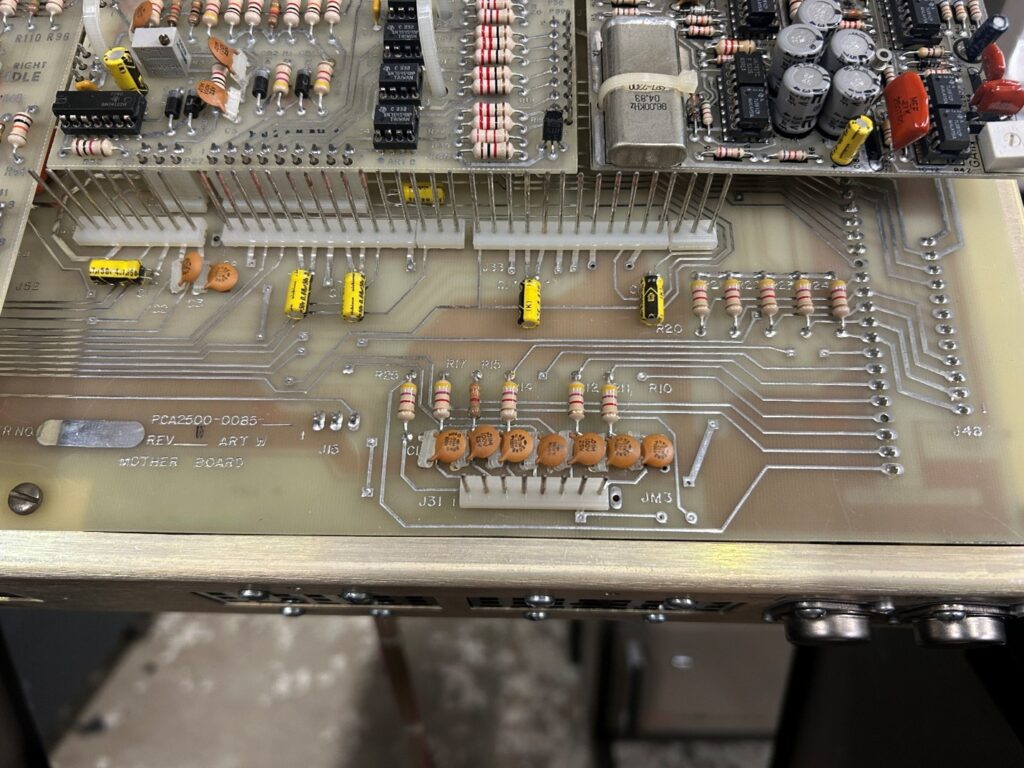

- Molex connectors used throughout. Multipin Molex brand connectors are used throughout the transport and audio electronics, and these are now very unreliable. Each connector must be cleaned, and the motherboards re-soldered, as the machine soldered connections (wave soldering during assembly) will crack and intermittent contacts will result

- bad solder joints on the Molex connectors in the power supplies must be re-soldered.

- intermittent contacts on the large Cinch-Jones connectors used at the power supply. These must be cleaned.

- ‘shadow’ switches are now failing, with the ‘cat’s eyes’ indicators jamming up. Fortunately in most cases, the switches are still functioning fine, but the mechanical on-off indicators have failed. Some can be replaced, some not.

- noisy capstan motor at high speed

- the hydraulic shock absorbers (gas shocks) that hold up the transport chassis have failed close to 100% at this point. These, however are found on Amazon for cheap.

- the main play/sync relay at the back of each audio card goes intermittent and noisy over time.

JH-110

This is the most popular reel to reel deck that MCI sold, from 1975 to 1984. It generally was sold as a ½ track model, but as per the links above, could also be ordered in ¼ track configurations if desired.

Overall, the deck works well, and has lots of adjustments for bias, levels and eqs. Individual controls are available for each speed, allowing the deck to be precisely dialed in. The tape counter was advanced for its time, and had accurate ‘return to zero’ functions, and memory locations as well.

The transport flips up to allow easy access to all of the PC boards, and even the back part of the transport also flips up, allowing service and access to the large motherboard that many of the transport boards are mounted to. The PC boards are high quality fiberglass, and there’s little chance of the PC board foils lifting when soldering or unsoldering a replacement part in place.

The shock absorbers seen down in the chassis on the left and right side of the transport are now completely worn out, and if you let go of the transport with it in the ‘up’ position, you’ll lose a fingertip or two as it slams down. Fortunately, replacement shocks are readily available on Amazon, although you’ll need to drill out one end of most of them, so that the hole fits over the stud on the chassis that it mounts to. The deck below shows that the transport can indeed remain in the service position, held in place with the new shock absorbers. Most techs (myself included) have relied on a handy 2 X 4, wedged into the corner of the transport to hold it up. Replacing the shocks is a better method though.

With the exception of the ‘cat’s eye’ push-buttons on the deck that can fall apart over time, all other push-buttons and switches are of very high quality, and seldom need replacement.

One serious weak point of the entire MCI series are the Molex connectors shown below. These go intermittent regularly, both due to oxidation of the pins, and due to the wave soldering method during manufacturing to hold them in place. The vibrations and transportation of the deck crack those solder connections, and a bunch, especially in the audio electronics and power supplies, need to be resoldered. The Molex pins should all be wiped down with DeOxIt sprayed on a cotton swab, with it then rubbed up and down on each pin. The amount of dust, dirt, and oxidation that come off these pins is incredible. DeOxIt also makes wipes that can be used, but the DeOxIt cleaner sprayed on a cotton swab is likely less expensive.

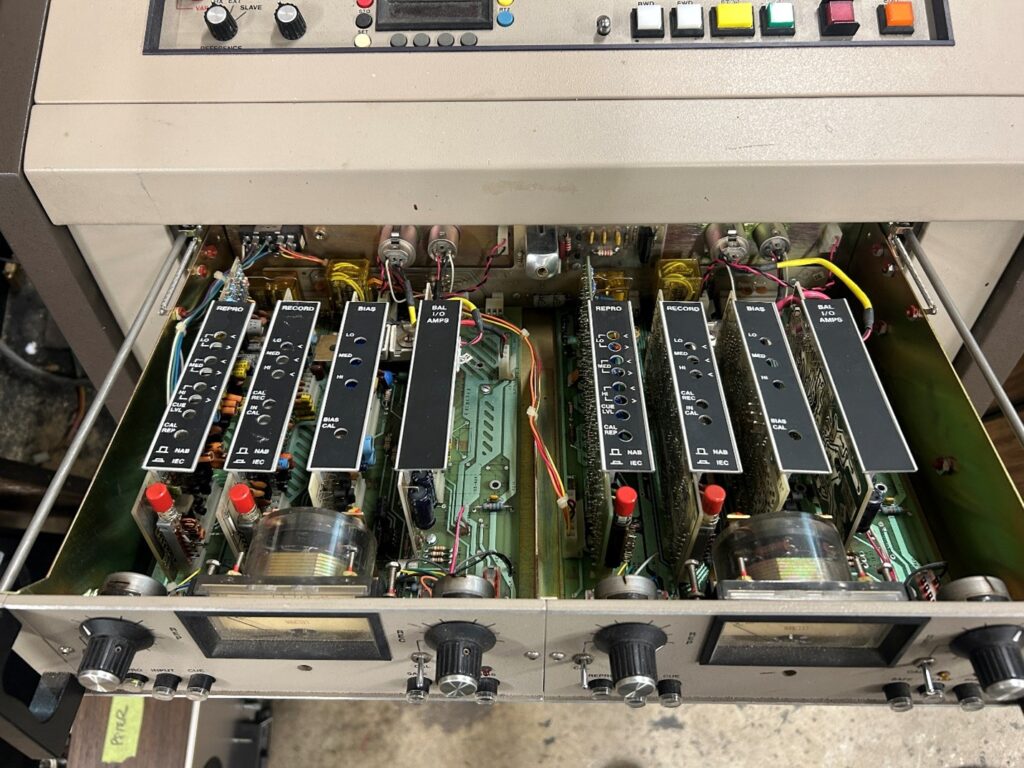

The audio electronics section pulls out right from the front panel as shown below. This allows easy access to servicing the entire audio section. Each channel is on its own module, that comes out of the audio section. Some studios would have spare audio channels or audio cards, allowing a quick swap in the case of a failure.

While each audio channel is completely separate, they do share a master bias oscillator located at the back of the audio tray. Fortunately, failure on these boards is rare, and adjustments of the master oscillator can be done with the audio tray pulled out.

There are individual audio cards for playback, record, bias, and the balanced audio input card. Each VU meter has two bulbs, one on each side, and these are normally burned out at this point. Fortunately, those push-in bulbs are easy to find online (part number 7327). The service manual is exceptionally well written, and following the calibration procedure is no more difficult than working on any other RTR deck.

Before doing any calibration on the deck, it’s highly advised to remove each audio channel from the deck, and re-solder the Molex connectors from the bottom, as many of them crack and cause problems. Once resoldered, and the Molex connectors are wipe with DeOxIt, they are generally reliable.

There are two large relays mounted to each audio PC board at the back. The one on the left controls the audio path of the playback head, and when tapped, the relays usually cause a ton of noise in the audio output. It’s never a good idea to use large and high current relays for a tiny audio signal as that from a tape head, as the smallest bit of oxidation will cause noise, and even a change in frequency response on the audio output. Fortunately, if the deck isn’t moved while recording or playing back, the noise generally isn’t an issue. As of this writing, (Jan 2026) we are working on a modern day equivalent to this problematic relay. Stay tuned!

Several production runs use the tall red IC sockets throughout the deck. It’s mandatory that these all be changed to machine type of sockets, as the red ones go intermittent regularly. Some get so bad that the ICs fall right out of them if the PC board is held upside down.

The MCI decks have a couple of other quirks, such as tantalum capacitors that can short out, causing smoke, but that’s pretty common now with any tape deck that uses tantalum caps.

One other potential source of problems for techs is that the transport uses a lot of 741 op amp chips, a common chip that came out in the late 1960s, and was used extensively in audio and other circuits in the 1970s and beyond. Normally these 741s can be replaced by later and current model chips, such as the NE5534, however specifically in the chip location that controls the DC offset on the analog torque board, only the early versions of the 741 chip can be used. Later 741s or modern day replacements won’t work properly. Fortunately, with the deck using 741 chips in a number of locations, a less critical 741 chip can be replaced by a modern chip, and then one of the original series can be moved over to the offset chip location, keeping the deck running.

Summary

Overall, once the quirks of each MCI deck have been worked out, these are a nice sounding deck, and can still be put into service in a home or a studio environment.

The tape handling is excellent, and since the deck was US made, many parts such as bearings are readily available. There are lots of MCI JH-110s being parted out, so finding specific parts generally isn’t difficult.

Since many of the JH series of decks are similar, boards and parts can be swapped out between them, making service relatively easy.

This article will be updated soon, adding the pros and cons of the larger JH-24, 2” 24 track deck.