Revox PR99

The Swiss company Revox made several excellent high end reel to reel decks, as well as higher end models designed for recording studios, radio and TV stations, branded under ‘Studer’. The Revox brand was used primarily for consumer machines. The history of Revox is found on Wikipedia here:

https://en.wikipedia.org/wiki/Revox

Revox was unique, and a leader in reel to reels in several ways. They generally stayed away from fancy lights and LED VU meters, and did not (to my knowledge) make any auto reverse decks. Instead, they concentrated on producing high quality decks built to last, and that were designed to be used 24/7 with minimal failures. Motors were direct drive, even back in the 1950s, resulting in simplified mechanisms/transports, and increased reliability.

Also unique about Revox was the fact that you could order the decks in whatever format you wanted to – full track mono, to ½ track stereo and ¼ track stereo. You could also order a Revox model with any two adjacent speeds, from 15/16 to 15 IPS. So, generally speaking, the Revox A77 and B77 were marketed as consumer decks, and were typically offered in 3 ¾ and 7 ½ IPS speeds, and ¼ track for home use, but could be custom ordered in any other version you desired. As a result, many A77 and B77s were used as ‘logging recorders’, which radio stations and emergency call centers would use to record incoming calls, and as a record for what was said on air. Depending on the speed and tape length used, you could expect up to 24 hours of recording time per side of the tape, and an automation device would set up 2 or 3 recorders to continually record, 24/7. As a result though, you need to be careful if you are blindly buying a used machine, as even the mono full track machines had two VU meters on them. AM radio stations would often buy full track mono machines, as stereo reproduction and recording wasn’t needed. I see 2-3 of these machines every year. Also beware that logging recorders are always very high hour machines, and while usually good as parts units, may have worn bearings or other issues not typically associated with much lower hour units.

Another quick note about logging recorders… the capstan shaft thickness was thinner than higher speed recorders, so while the motors will interchange with higher speed units, the speeds will be different due to the thinner capstan shaft. The capstan shafts do come out of the motor assemblies, so they can be swapped if required, however a different capstan shaft may bind due to the tight tolerances used. Also, while the various audio cards can be changed between tape decks, the recording and playback equalization changes between speeds, so an audio card out of a logging recorder won’t work properly in a higher speed recorder, and vice versa.

Revox/Studer is known for their flat frequency response, generally more so than similar decks made in the USA or Japan. This is generally thought to be due to the heads that Revox manufactured themselves (or had made for them), which managed to eliminate the typical 3db bass boost around 50-80Hz that were characteristic of many other decks.

Typical frequency response for a Revox deck at 7 ½ IPS. Flat from about 30Hz to 22Khz +/- 1db with ATR MasterTape

This can be good or bad, all depending on your viewpoint. Properly set up, a Revox reel to reel can be adjusted to be flat from about 30Hz to 20Khz, +/- 1db. This allows recording and playback to be very true to the source material… if that’s what you want. Many recording engineers specifically do NOT want a flat response, as they want the tape deck to add a ‘tape sound’ to the recording. For example, if you make a recording from a record or CD onto a typical Akai/Teac/Ampex/Sony reel to reel, you likely will notice a slight boost in the 50-80Hz range, making a bass drum sound fuller and larger than it actually is. A lot of people state that a reel to reel copy of a CD sounds ‘better’ than the original CD. This is likely due to this bass boost. With Revox designing their own heads, they got rid of this boost in the bass region, making the recording sound as close to the original source material as possible. You decide for yourself if this is the reproduction that you want. A lot of digitizing labs do use Revox and Studer decks, so that the playback of an old tape isn’t colored by the added artifacts of the reel to reel deck itself.

Revox models

There are likely more comprehensive lists of the various Revox models out there on the internet. We have left out the ones that we haven’t seen through our shop yet. A good marketing writeup is right on the Revox site itself:

https://www.revox.com/en/classics/reel-to-reel-machines.html

Revox G36

Revox G356

We’ve seen a few of these early 1960s tube models through our shop. The build quality is excellent. Three direct drive models handle the movement of the tape, and the overall transport is the basis of many later Revox models. The electronics are superbly wired, and relatively easy to service. The entire chassis comes out of the case, exposing all sides of the deck.

A low hour machine can perform as well as a later deck with that ‘tube sound’, although we’ve seen a few of these decks through here with very worn heads, and replacements are hard to find. Depending on how the deck was stored and used, some of the plastic pieces are brittle, and can break if not handled carefully.

While the capstan motor is direct drive, the switching between the speeds is done via a multi-layer 2 position switch under the chassis. This switches motor windings, and changes the eq settings within the record and play electronics for a flat response. We’ve seen one deck where the motor contacts on the switch had burned out, rendering the deck dead at 3 ¾. Despite our best attempts, we could not locate the correct switch for the deck, and we wrote it off.

We’ve had a number of G36 decks through the shop in the last few years. Overall, they hold up well, more so than the A77s, which are 5-10 years newer. Weak points so far are plastic parts, like the tape counter that crack and split apart, one case of the 3 ¾ and 7 ½ IPS speed switch with bad contacts (the 120 volts flows through the switch causing arcing, and eventual bad, non-repairable contacts), and other odd piece breaking due to age. There are several versions of the G36, and in the case of the bad speed switch, the replacement ordered on eBay was just different enough not to fit the model in for repair.

Not nearly as many G36s were sold compared to later Revox models, so if an oddball part breaks, you may be without the deck for months looking for a replacement used part.

A77

Revox A77

There are many A77s on the used market today, as they were a very popular deck in both home and pro settings. Many famous musicians (Jimmy Page, Robert Fripp, amongst others), used the A77 and B77s in their studios, and can be heard on many records made between 1967 and 1980.

Thom Yorke of Radiohead using a Revox B77

There were 4 versions of the A77, from the Mk 1 to the Mk4. Overall, the decks were largely similar between versions, although the later versions would allow you to go from fast wind to play without going through ‘stop’. The other changes were primarily cosmetic, as shown in the below link, which is an excellent summary of the A77:

http://www.reeltoreel.de/worldwide/A77.htm

Overall, the A77s generally need a complete rebuild due to age at this point, but when restored, are an excellent sounding deck, at a lower cost than the later model B77s and PR99s.

As of October 2021, many A77s are not holding up well. Recapping every A77 and replacing all of the trimpots is mandatory, we strongly recommend doing it to all clients that bring A77s in for repair. Pricing on some parts (like the VU meters) have skyrocketed, and it’s very common for decks to come in with at least one meter being stuck, due to glue bonds separating within the movement itself. 10 years ago, An A77 VU meter was about $15 USD on eBay. Now, due to demand, they are closer to $90 USD each. Capstan motors are failing due to age, and if in storage for many years, the bearings can seize up. So beware, a partially working A77 can run $500-800 USD for a full overhaul, with no guarantees that a major part may not fail within a couple of years due to age. ON the positive side, there’s tons of A77 parts out there to keep your A77 going.

B77

Revox B77

There were two versions of the B77, the plain B77, and the MkII. The vast majority of Revox decks sold were the MkIIs, which have a pitch control built into the deck under the front panel flip-down cover. While the pitch control is handy for musicians, it’s generally of little use to home stereo users. While there were some minor changes to the electronics, generally speaking, the pitch control (Revox calls it ‘Vari-speed’), was the biggest difference between the two models. These are excellent work horses that sound great, and fully serviced, are very reliable.

Generally, the B77 came as a ¼ track, 3 ¾ and 7 ½ IPS model.

A700

Revox A700

There’s an excellent write-up on the A700 here:

http://www.reeltoreel.de/worldwide/A700.htm

Our spin on it: Every manufacturer makes a lemon in their product lineup, and in our opinion, the A700 was the one for Revox. The concept was sound originally: Make an ‘all in one’ tape deck that will eliminate the need for a preamplifier in the stereo system. The A700 has a magnetic phono preamplifier in it, so you can connect a turntable directly to the A700 for recording albums. It also has a couple of auxiliary inputs for other music sources, as well as microphone inputs. This unit was state of the art in the 1970s, with slide controls instead of rotary level controls. The tape transport was excellent, and looked more like a pro Studer machine than the simpler tape path of the A77 and B77 models. Three speeds, from 3 ¾ to 15 IPS made it a versatile machine overall. Finally, it was portable, with a handle on top.

Here’s the downside of the A700, outside of the general pros and cons listed further down in this article:

Handle: time has not been kind to the carrying handle, and they are now brittle. More than a few times the carrying handle has snapped on the A700, causing the deck to fall.

VU meters: failure of one or both VU meters is very common on the A700, and is a mechanical failure of the movement itself. Working used replacements typically run $200 USD on eBay, and the meter movement was unique to the A700. Other Revox VU meters will not fit into the A700.

Slide Pots: the slide pots can be intermittent, and may or may not be solved by cleaning the controls with DeOxIt.

There are other age related problems with the A700, but the most significant issue is that nowhere near as many A700s were sold as the A77 and B77, and therefore parts for the A700are not readily available. A serviced, well running A700 sounds and works great, but in our opinion, will eventually have a failure that cannot readily be repaired.

PR99

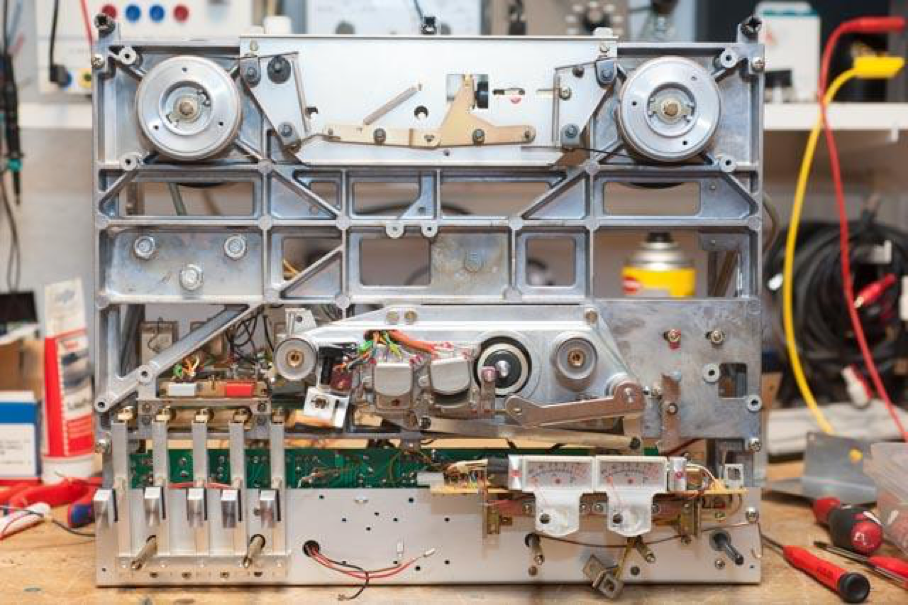

Revox PR99

The Revox PR99 was generally thought to be the semi pro version of the B77. While the design was similar in several respects, the B77 and PR99 share very few interchangeable parts, as the electronics were different in many ways. Typically, the PR99 came in ½ track, and 7 ½ and 15 IPS speeds, but could be ordered in other formats as well.

The most obvious differences between the PR99 and the B77 is that the PR99 has balanced inputs and outputs (XLR) compared to RCA connectors. Mating the deck to a studio mixer was a snap, and made it popular in the pro realm of broadcast and studios. The PR99 also has a ‘tape dump’ button, stopping the takeup reel motor, which was useful for editing and splicing tape. A couple of ‘sync’ buttons allows the record head to be used as a playback head – useful when wanting to play back one channel while recording on the other.

There are three versions of the PR99. Mk1 was missing the splicing block on the front of the deck, and the MkIII changed the front color of the deck, and simplified the front panel layout of the deck. Overall, the PR99 are an excellent machine for home or pro use.

More information on the Revox PR99 is here:

http://www.reeltoreel.de/worldwide/PR99.htm

Pros and Cons of Revox reel to reels

While this list isn’t complete and is based on personal experience, servicing 100s of Revox decks over the last 40 years, it does provide an overview of what to look for when buying a Revox. The ‘con’ list will appear to be longer than the ‘pro’ list, although as service techs, we see the problems with all reel to reel decks a lot more than decks that continue to run well for decades.

| PROS |

Frequency response

As previously stated, Revox decks can be dialed in for a very flat frequency response, more so than many other decks. For a reference deck, it’s difficult to beat a fully serviced Revox.

Simplicity of Design

The transport of Revoxes are very gentle to the tape, which is why many of the decks are used to archive and to play master recordings, as well as old acetate tapes, which can now be brittle. Both the transport and electronics are relatively simple to service, and even the novice can check brakes or change PC boards with ease.

Revox A77 transport

Modular Design

Because Revox was designed to be run for long periods of time, they are very serviceable. For facilities with multiple identical machines, radio stations would often stock a spare machine, which sometimes was used to swap boards out of, to keep downtime to a minimum. Most of the electronics on the A77 and later models are on modules that can be replaced with nothing more than a screwdriver, with no soldering required. Things like motors are also on quick-disconnect terminals, that allow them to be easily removed.

Revox B77 module

Long Life Heads

Based on the gentle curve of the head shape, Revox heads are less prone to get a groove worn into them as compared to Teac, Otari and other similar decks that come to more of a point where the tape touches the heads. These prevents high frequency loss, and the tendency for tape to move in and out of a groove worn into the head, which causes level and high frequency response changes during record and playback.

Having said that, we have seen some of the documenter Revox decks come in with heads that were completely worn out, simply due to 1000s of hours of use of the deck

Revox B77 head assembly

Almost all parts are still available for many Revox models out of Switzerland. While Revox was sold after Willi Studer, the founder of Revox died, they still support these analog machines. Of course, the prices for parts are at a premium, however it’s nice to know that something as obscure as covers and hardware along with specialty parts are available from www.audiohouse.ch

| CONS |

Revox has an arm’s length list of problems unique to the design of the decks, and based on us servicing literally 100s of decks over the last 40 years. Here are some of the typical problems that can happen with Revox.

Capacitors

One of the most common failures of all Revox decks are capacitor issues, and here’s why, as there are two different scenarios that can happen:

Revox used between one and nine 0.47 uF capacitors in the motor circuits of the vast majority of Revox tape decks. Over time, these capacitors develop cracks, and then can short out, usually in spectacular form. These capacitors will short out without warning, sometimes with an audible BANG, followed by a cloud of smoke. The brand of the capacitors are Rifa, and they are known for this problem. Usually the fuse(s) will not blow in the tape deck, however these capacitors do need to be replaced for proper operation. Usually, no other parts are blown within the tape deck, despite the spectacular failure of these capacitors.

Here’s a bag of capacitors from a PR99 model. This is typical for a Revox that needs recapping, it’s 6-8 hours’ worth of work, plus calibration and alignment.

Revox also used a brand of electrolytic capacitors throughout their decks by the brand name of Frako. While most capacitors will lose value over time, and some brands can and will leak electrolyte out of the capacitors (and the Frakos are known to do both), they have the added unwanted feature of shorting out at random without warning. This can blow fuses or other parts within the deck, and again, this happens at random without warning.

A tech buddy in Los Angeles summarized the Revox Frako capacitor as follows:

“Quote the client between $600-$1500 to replace all capacitors in a Revox (model dependent), and they freak out. Quote them $300 to troubleshoot and replace the one shorted capacitor, and you’ll have a client for life, as every year another capacitor will short out and fail, and they’ll bring the deck back yearly for service. Those are the two options the client has.”

Generally, we are not a fan of a full recapping on any model of tape deck, as capacitors aren’t known to fail that often, even at the 40-50 year point, however with Revox/Studer (and Technics RTR decks, covered elsewhere), the failure is so common that we will not sell a Revox or Studer without them being fully recapped.

A blown Rifa capacitor as found in many Revox machines

Counter belts (A77 and B77)

It’s typical for counter belts to fail in any tape deck, and stretching of the counter belt between the takeup reel table and the counter is no exception. Many of the earlier mechanical tape counters in the A77 and B77 have a plastic/nylon toothed belt on the back of the counter itself that generally goes brittle and breaks, rendering the counter useless. These little belts are horrifically expensive online, but we’ve found that a 3.2” rubber belt works just fine in its place for significantly less.

Revox counter belt

Slick capstan motor shaft

This problem took us several hours to figure out when we first saw it. The symptom is excessive wow in the tape speed, especially as the tape gets to the end of the reel. We spent hours adjusting brake and pinch roller tension, only to finally figure out that the capstan shaft on the Revox goes slick over many hours of use, where the tape touches the shaft. Eventually, the capstan shaft is so slick that it no longer grips the tape, despite the pinch roller pressure being where it should be at.

The solution is to remove the capstan shaft and get it blasted with aluminum chloride.

The capstan shaft on the left shows a shiny band where the tape has worn the shaft slick from 1000s of hours of tape running through the machine. This causes a lack of grip between the capstan, the tape and the pinch roller, causing wow, especially as the tape nears the end. The capstan shaft on the right is new old stock, showing no wear.

More information to follow in a separate article on how to do this.

Broken Toggle Switches

An annoying but straightforward fix is to repair or replace the broken toggle switches on a Revox B77 or PR99. The design of the toggle switch is flawed, in that it is very easy to snap them with any kind of sideways pressure of the switch. The switches are available on eBay on a regular basis, or a repair kit is available from Nagravox, here:

We use those switch kits regularly to repair the toggle switches.

Revox broken toggle switch

Lack of module compatibility

Since Revox was constantly upgrading their tape decks, they had several versions of most of the boards found within each tape deck model. Sometimes the changes were minor, sometimes the boards were completely redesigned for better performance or reliability. The problem is that some boards will not be compatible with other versions. In addition, certain boards had components changed to suit the tape speeds available with each deck, and differing speed models won’t work properly in other decks due to the different eq curves set up in them. For example, a 7 ½ and 15 IPS reproduce/playback board will make the playback of a 3 ¾ and 7 ½ IPS deck sound dull due to the increased treble rolloff built into the board with the faster speeds. Other modules may not work at all in other versions of the deck. It’s always best to repair the exact board that has failed within a Revox rather than trying to make a used board on eBay work in the deck you are trying to repair.

Capstan Motor servo sensors

All Revox capstan motors use the equivalent of a tape head on the side of the capstan motor to pick up the magnetic changes in the flywheel, to feed back to the capstan PC board for capstan speed regulation. On occasion these sensors go brittle and will break. If the sensor shifts away from the capstan motor, and the magnetic pulses go missing or are reduced in amplitude, the capstan will run away, and run at an excessive speed. More nefarious is if one side of the plastic mount breaks, and the sensor shifts away slightly from the capstan flywheel. This reduces the amplitude of the feedback pulses, and the speed can fluctuate, especially at the slower speed. This took us hours to figure out! So, if the capstan shaft isn’t slick, the capstan control board has been recapped, and you’re still getting rhythmic wow, check to see if the wow happens on every rotation of the capstan motor. Then check the gap between the flywheel and the sensor. This gap should be as small as possible, without the sensor hitting the flywheel.

Revox capstan motor, with the sensor on the left side

Bad Bearings on Capstan motors

Over time, the capstan motor bearings and shafts can warp slightly due to use and heat. What we found useful is to see how long the capstan flywheel spins after you power the deck down. A typical spin time is 3-5 seconds, indicating a straight shaft and good bearings. If the flywheel comes to a halt in 1-2 seconds, then something is amiss, and is applying too much friction to the shaft. Failure of a bearing or of the motor is near.

We’ve also found that the shafts and bearings can warp slightly after the capstan motor is warm. We’ve recently had several decks that would start to have wow or flutter in them, or seize up after they are warm. Motor replacement is the only option.

Gooey Pinch Rollers

Some Revox decks came with green colored pinch rollers. These were sold by Revox, but were also available aftermarket. These pinch rollers can go gooey, and even liquify, sending green goo through the inside of the deck. If you have a green colored pinch roller, we strongly recommend that you send it to Terry’s Rubber Rollers for rebuilding: